Delivering Quality and Safety

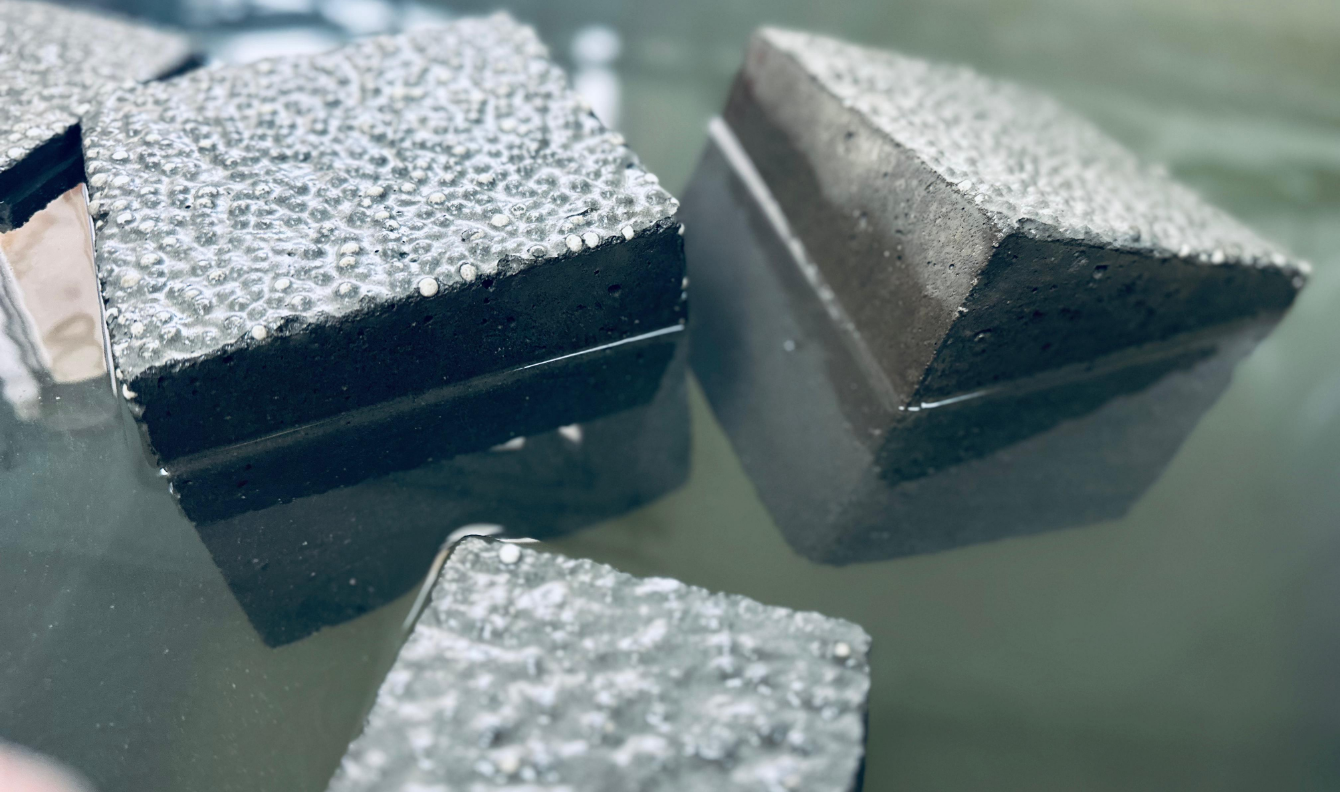

Our manufacturing facilities utilize advanced systems and stringent protocols to ensure every concrete delivery meets the highest standards. Raw materials like cement, sand, and gravel undergo rigorous quality checks before entering our centralized batch plants.